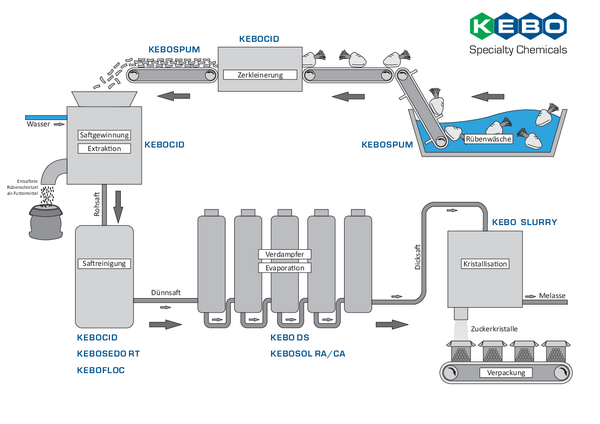

Specialty chemicals for cleaning processes in the beet sugar production

In beet sugar production, various chemical products play a crucial role in making the production process more efficient and of higher quality.

scale preventers for evaporating stations: Products such as our KEBO DS are in demand in the beet and cane sugar industry, as they ensure continuous and energy-efficient sugar production. These scale preventers stabilize deposit-forming calcium salts in solution and enable their separation from sugar crystals during centrifugation. Facilitated final cleaning after the campaign is made possible by the use of degreasers. KEBO DS is characterized by its nitrogen and phosphate free,

low molecular weight formulation and is able to keep calcium ions in solution in the presence of oxalate-, sulfate and phosphate ions at sub-stoichiometric dosage even under conditions that normally lead to precipitation of the deposit formers (so-called THRESHOLD effect). In addition, KEBO DS exhibits excellent dispersing properties and remains hydrolytically stable and non-volatile at high temperatures. It is added to the thin juice before entering the evaporation station by means of a dosing system.

Crystallization medium: Uniform sugar growth is crucial for the quality of the end product. KEBO SLURRY is a ready-to-use mixture of finest, uniformly ground sucrose particles

suspended in a highly viscous liquid. This ensures particularly homogeneous crystal growth, resulting in defined sizes and uniform aspect ratios for the sugar crystals. Interestingly for exporting sugar producers, KEBO SLURRY does not use common alcohols for sugar dispersion and is therefore Kosher and Halal certified.

Infection control: Bactericides are dosed to prevent and remove organic growth. Our KEBOCID products are in demand here and kill the organisms with multiple shock doses if contamination is already present. Subsequently, low regular dosage prevents renewed growth

Defoamers: To ensure continuous production, defoamers are necessary for both interior and exterior use. Our KEBOSPUM series offers specialized defoamers depending on

temperature and application. These defoamers show an equally high foam-destroying power in all liquids, regardless of the pH value and the type and concentration of dissolved substances. They are not volatile in steam and show highest effectiveness in a certain temperature range (from 40 °C and higher) in interior operation

Alkaline cleaners: Special mixtures of dispersants and surfactants are used to remove the organic content in deposits and convert acid-insoluble salts into acid-soluble calcium carbonate. They enable the solid surfaces to be broken up and the alkaline cleaning solution to penetrate deeply into the deposits. The use of additives for alkaline cleaning greatly improves the cleaning effect and optimally prepares the scales for subsequent acid cleaning.

Corrosion protection for acid cleaning (LITHSOLVENT series): For reliable protection of metallic surfaces during acid cleaning, our LITHSOLVENT products are used. Depending on the temperature,

cleaning duration, metal type and acid, specialized products are used that take into account the common materials used in evaporators and are optimized for a desired chemical cleaning

The proper application and dosage of these chemical products are critical for a smooth and efficient production process in the sugar industry. It is important to consider the specific needs and circumstances of each sugar factory and to use the products responsibly to ensure the quality of the final product while protecting the equipment. We will be happy to assist you in choosing the right products, with appropriate tests and trials in cooperation.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.