Corrosion inhibitors for chemical cleaning

Corrosion protection can be carried out in several ways. Some of the measures are already applied during material production, others only afterwards. Thus, on the one hand, the surface can be coated with non-rusting substances or mixtures or provided with chemical corrosion inhibitors, so-called (corrosion) inhibitors . Surface coating includes, for example, galvanizing and painting.

KEBO offers chemical corrosion protection for chemical cleaning, water treatment and the steel industry.

Water treatment can be found here.

Increase the profitability and long-term protection of your equipment with our highly concentrated LITHSOLVENT corrosion inhibitors for dry cleaning

The right inhibitor depends on the acid used. The acidity, in turn, depends on the material of the plant and the deposit formed by the processed raw material. We offer a wide variety of corrosion inhibitors for all types of scaling, acids and materials.

You can find a selection of our portfolio here.

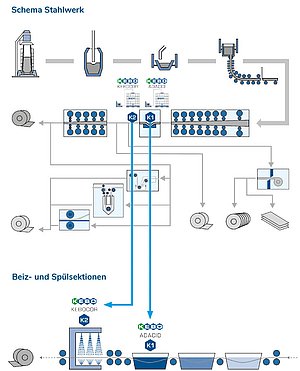

Pickling inhibitors for measurable economic success

Acids are used to remove the oxide or scale layer and other corrosion products from the metal surface during the pickling process. An oxide layer (scale) is formed on the surface of metal during production and thermal treatment (due to reaction with atmospheric oxygen). This layer interferes with further processing of the material. In the process, the base material is also undesirably attacked. Material losses, unnecessary acid consumption as well as pickling damage, i.e. pore formation, overheating, hydrogen embrittlement, poor pickling atmosphere, etc., are the often costly consequences.

Our response: ADACID inhibitors – indispensable in many applications

We develop pickling processes, the fundamentals of which are established by studying the surface conditions of metal samples.

Our highly effective ADACID inhibitors, manufactured by us for hydrochloric and sulfuric acid, meet the highest requirements.

While the metal dissolution rate is lowered, the oxide dissolution rate is only slightly reduced.

The economic advantages in operation are clearly demonstrated:

- Material savings

- No over-pickling

- Quality improvement

- Acid savings

- No foaming in regeneration plants

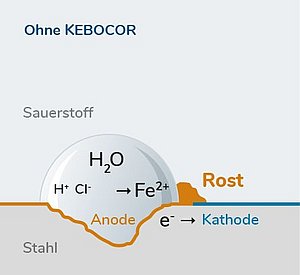

Highest quality for clean and protected surfaces: KEBOCOR

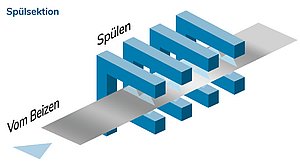

After pickling, it is important to rinse the steel strips thoroughly to remove all residues of acid and ferric chlorides from the surface. This is the only way to prevent renewed corrosion and staining, especially in the form of iron hydroxide brown stains. Discover the ideal method for effective follow-up care with KEBOCOR! Our KEBOCOR grades are the suitable neutralizing agent wherever value is placed on clean and protected surfaces.

1 Optimal long-lasting material protection

KEBOCOR grades prevent tarnishing and rusting of steel surfaces during the rinsing process after acid pickling.

2 For reliably fast drying after treatment

To achieve optimum results, the rinsing and neutral baths must be run as hot as possible to ensure fast drying of the material after treatment.

3 Buffer capacity prevents rust pustules on metal surfaces

The buffer capacity of KEBOCOR grades prevents the formation of different pH ranges on the surface, so that no stable local anodes can form, leading to rust pustules.

4 Rinsing neutralizes acid residues

Pickling and rinsing are followed by neutralization. During

this process, the acid residues remaining on the surface and in the pores

are neutralized. Expediently, a good

neutralizing agent also contains passivating substances to effectively prevent subsequent

rusting during storage for a certain time.

5 The perfect pH range is important

Optimally, neutralization takes place in the pH range of 10–11.

In this range, the neutralized surfaces obtain a more beautiful and brighter appearance than when working in the pH range of 13–14,

i.e. in solutions containing caustic soda.

The advantages of passivators added to the rinse water are clear:

- Prevent corrosion

- Form a protective layer

- Inhibit predominantly cathodic partial reaction

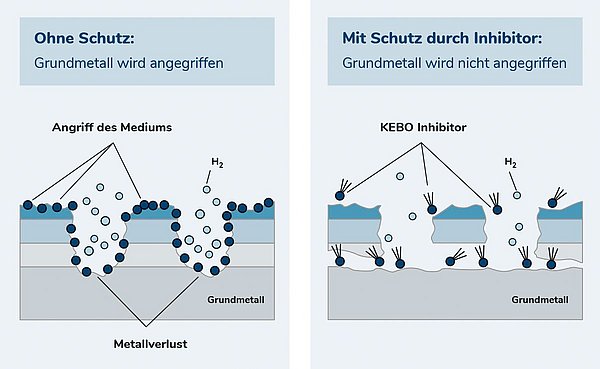

Inhibitors as material protection when using acids

Without the use and protection of inhibitors, there is an attack of the acid on the surfaces to be cleaned . After only a few cleaning processes, damage to the carrier material occurs. With metal surfaces, for example, this can result in so-called pitting (metal damage)

Corrosion inhibitors and their function

Corrosion inhibitors are used as material protection when using acids. Inhibitors have a special chemical effect that influences a chemical reaction in such a way that it is slowed down, inhibited or prevented completely. In the case of acid cleaners, this prevents the acid from attacking the material to be cleaned.

Or with other words: The inhibitors form a monomolecular protective film on the metal surface without hindering the dissolution of the deposit by the acids. The result: optimum cleaning performance with simultaneous protection of the substrate.

You are working with acids? Then use our highly concentrated inhibitors for admixture in acids.

Necessary properties of a good corrosion inhibitor

- High stability against aging, oxidation or reduction.

- Temperature stability

- Immediate effectiveness on addition

- No prolongation of reaction time on addition

- High protection value at low inhibitor concentration

- .No interfering influences on the acid mixture or further processing of the treated metal

Hereby, the analysis of the scales is the first factor to be considered, followed by the in-depth evaluation of the substrate. On this basis, we recommend a comprehensive cleaning concept that is optimally tailored to your needs.

With our LITHSOLVENT corrosion inhibitors, you make a good choice!

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.