State-of-the-art protection of water cycles

Our goal is to conserve precious water resources by providing advanced cooling and industrial water treatments. With our products, we protect heat exchanger surfaces and piping from scaling, corrosion and microbial growth.

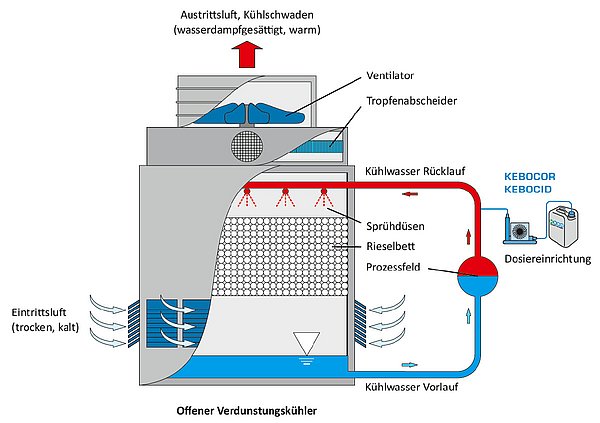

Our KEBOCID products are essential to prevent microbial growth and algae formation in open and closed circuits. In addition, our KEBOCOR and KEBOPLEX products provide hardness stabilization and corrosion protection for cooling and process water systems.

Corrosion protection and water treatment of plants

in the closed system:

- Our corrosion inhibitors, such as KEBOCOR 206 Cu, provide optimal protection for steel and copper in aqueous solutions. They are particularly effective in preventing idle time corrosion.

- KEBOCOR 213 offers a synergistic mix of organic and inorganic inhibitors that provides the best corrosion protection in closed and semi-open water systems.

in open, water-bearing systems:

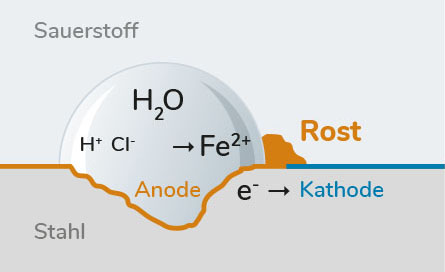

- In hard cooling and service waters as corrosion inhibitors for iron and copper alloys, our KEBOCOR 224 L is used. A combination product of corrosion inhibitors, hardness stabilizers and dispersants for open, water-bearing systems. It prevents the precipitation of alkaline earth carbonates and the deposition of suspended solids on metal surfaces. It is also hydrolysis and temperature stable and compatible with free chlorine (Cl2). The specially formulated organic nitrogen- and phosphorus-containing corrosion inhibitors produce thin, firmly adhering top coats on steel and non-ferrous metal surfaces.

- In open cooling systems, with high calcium and bicarbonate concentrations, for deposit prevention and corrosion protection of steel, we recommend our hardness stabilizer and corrosion inhibitor KEBOCOR 226. It contains low molecular weight anionic polyelectrolytes and organophosphates as hardness stabilizers. In sub-stoichiometric amounts, they are able to hold alkaline earth ions in solution in the presence of high carbonate hardnesses (threshold effect). KEBOCOR 226 is hydrolytically stable and resistant to wall temperatures up to 200 °C. It is also compatible with free chlorine (Cl2). The corrosion protection is produced by a special organophosphorus component. It forms thin but dense top coats of calcium and iron compounds on the metal surface.

.

- As a corrosion inhibitor, hardness stabilizer and dispersant in open cooling systems that have low acid capacities (low m-value) and/or low calcium contents (make-up water softening) our KEBOCOR 241 is used. It is a corrosion inhibitor for steel and copper alloys in open cooling systems. Due to the dispersing properties of the higher molecular weight polymers it contains, KEBOCOR 241 prevents the particles from agglomerating and settling on walls of the system. It prevents hardness precipitation and disperses dirt particles. Likewise, precipitations from supersaturated solutions are prevented - by contained polyelectrolytes in sub-stoichiometric dosage.

.

Infection control – biocide

Also, we recommend our biocides, our KEBOCID products, such as the KEBOCID 310.

KEBOCID products are dosed to prevent and remove organic growth. If contamination is already present, the organisms are killed with repeated shock dosing and then renewed growth is prevented with low regular dosing. Industrial water systems generally provide ideal growth conditions for microorganisms (bacteria, molds and algae) as well as microorganisms (paramecia, water fleas, amoebae, rotifers, etc.). Algae require sunlight to reproduce. Molds and many strains of bacteria grow in oxygenated (aerobic) systems e.g., open cooling water circuits, air scrubbers, etc.; other bacteria multiply in oxygen-free conditions such as closed circuits, the sump of open systems, under slime layers and deposits). The organic and inorganic substances dissolved in the water are metabolized.

Frequently, however, parts of the system (e.g. cellulose in wooden cooling towers, plastics or iron ions) or the dosed water conditioning agents serve as nutrient and energy suppliers for the microorganisms.

The consequence of microbial growth is biofilm formation on the surface or in the sump of the system. In addition to the deterioration of system parameters (heat transfer, clogging of pipelines, etc.), biofilms lead to the build-up of potential differences on the metal surface, which accelerate the microbially induced corrosion process (biofouling).

One more health aspect should be mentioned. It cannot be ruled out that pathogens can also survive (e.g. in air scrubbers) or even multiply. Based on the briefly outlined negative effects of microbial growth in industrial water systems, it makes technological and economic sense to prevent the proliferation of microorganisms through targeted disinfectant dosing.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.