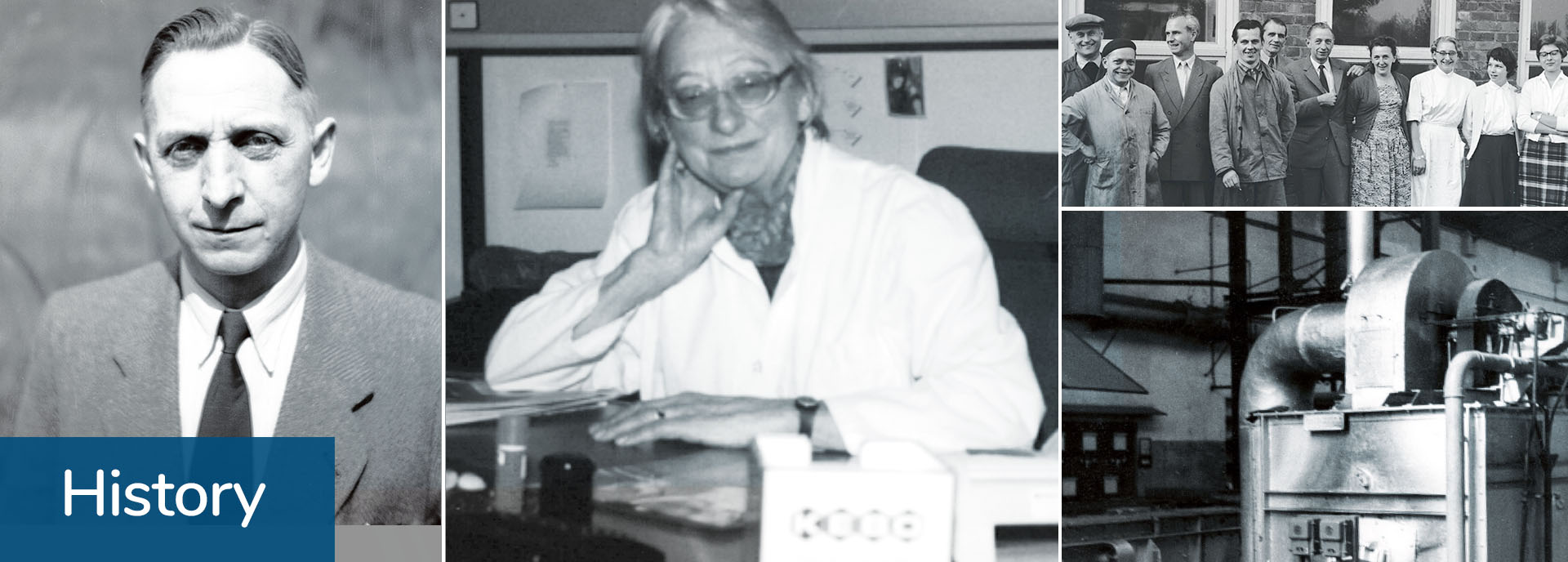

A fascination with steel and its reaction to external chemical influences - this passion united the two chemical engineers Alfred Keller and his student friend Albin Bohacek when they laid the foundation stone for today's company Keller & Bohacek GmbH & Co. KG, KEBO for short, in 1926. Soon after, they realized that their enthusiasm had led to a depth of knowledge that had not previously existed in the application-oriented industry, leading to some problems and uncertainty.

The two chemists did not want to resign themselves to this. They therefore decided to support companies with their knowledge in a trusting manner and on an equal footing when it came to cleaning and protecting their plants against corrosion. Thus, the passion of the founders, who included Getraud Keller, Alfred Keller's wife, gave rise to a mission that remains deeply rooted in KEBO's DNA to this day.

The passion for steel and its reactions to external chemical influences runs like a thread through the history of the founding family. Alfred Keller's wife and one of their three daughters were also chemists. Alfred Keller's granddaughter Alissa Zeller also holds a doctorate in chemistry and lives on the original mission as the impetus for KEBO's entrepreneurial activities to this day.

The present company Keller & Bohacek GmbH & Co. KG was founded on 02 January 1926 as "Rostschutz GmbH", with a focus on the construction of galvanizing plants in Halle, Germany. The early entry into the production of pickling inhibitors laid the foundation for today's orientation as a specialized chemical company.

With the switch from brass to steel starting in 1930, the need for new protective inhibitors in the acid treatment of metallic surfaces grew in the metalworking industry. With our deep knowledge of corrosion protection, we were able to win over the sugar industry as a customer as early as 1943. Our products protect production equipment against acid attack during chemical cleaning.

In the 1950s, the move to the current headquarters in Düsseldorf Rath and the founding of the partner company , KEBO FRANCE SARL in Paris. The new group of companies strengthened the KEBO brand's position within Europe and laid the foundation for joint international expansion in all business areas. in 1993, KEBO FRANCE moved its headquarters to Ozoir la Ferrière.

Sometimes it pays off to look at how others do it. The naming of our encrustation preventer KEBO DS is a good example of this: Do you know where the name comes from? "Déesse" is the French word for goddess, which Citroën used to name its classic car. This approach inspired us, because it is exactly the right name for the way our product works. Even today, KEBO DS ensures continuous and energy-efficient production. In the sugar industry, for example, scale-forming calcium salts are stabilized in solution and separated from the sugar crystals during centrifugation.

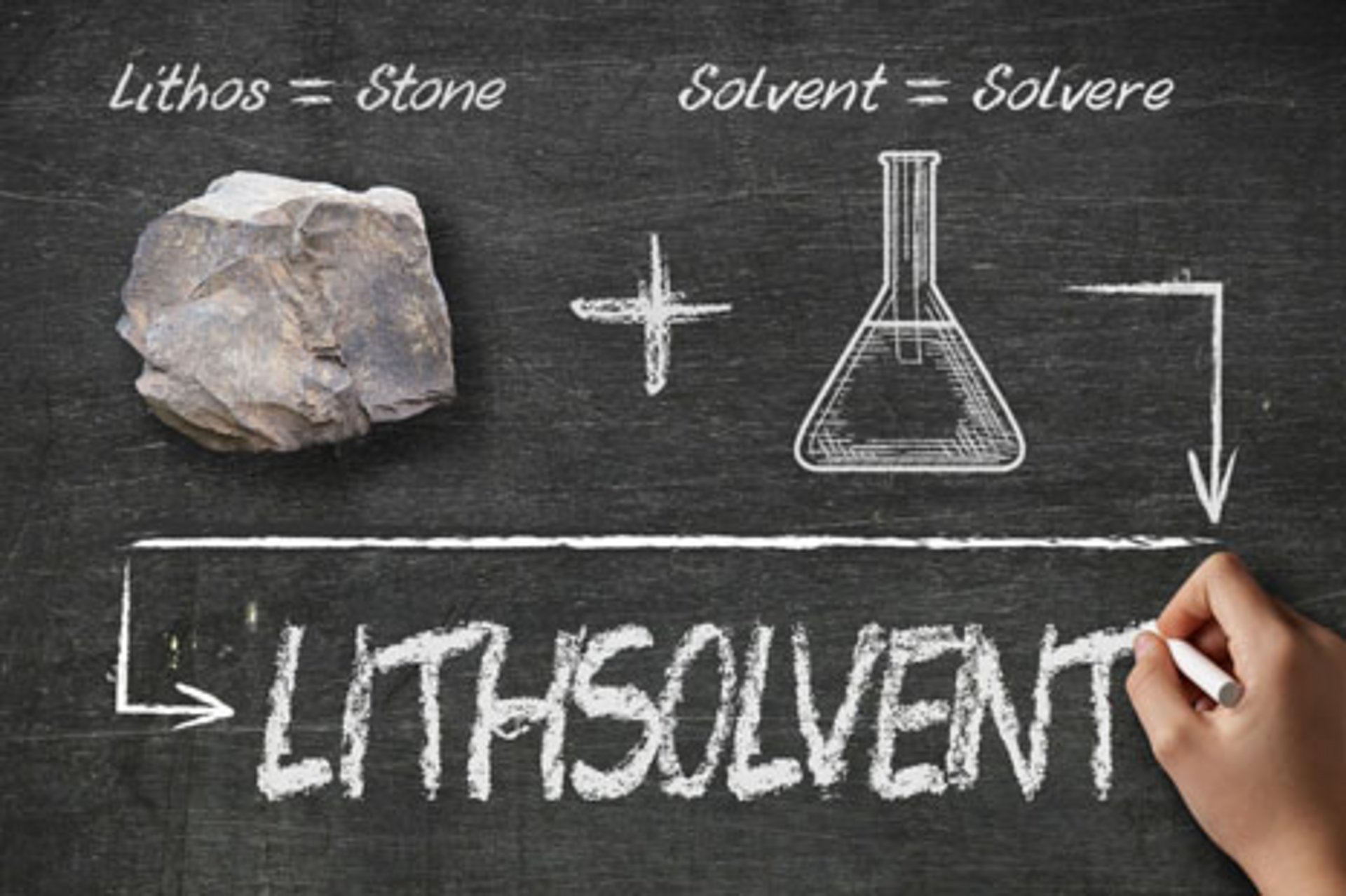

In the case of the naming of LITHSOLVENT, our co-founder Gertraud Keller, also a chemist like her husband Alfred, put her creative heads together and made use of Greek and Latin: Lithos means stone and solvent – as a derivative of salvere – means to dissolve. Nomen est omen: The surfactants contained in our LITHSOLVENT products help the acid to infiltrate the deposits. The reaction of the acid with the metals produces hydrogen gas, which blasts the scales from the substrate. Once the metal surface is exposed, the inhibitor will protect it from further attack by the acid. At the same time, detached dirt particles are dispersed.

The new millennium was all about growth for KEBO. In 2007 the new production hall was built. With the expansion of production capacity, KEBO was ideally positioned to meet the increasing demands of the market and further expand its position as one of the leading specialty chemicals suppliers for chemical cleaning, water treatment and corrosion protection of industrial production facilities.

.

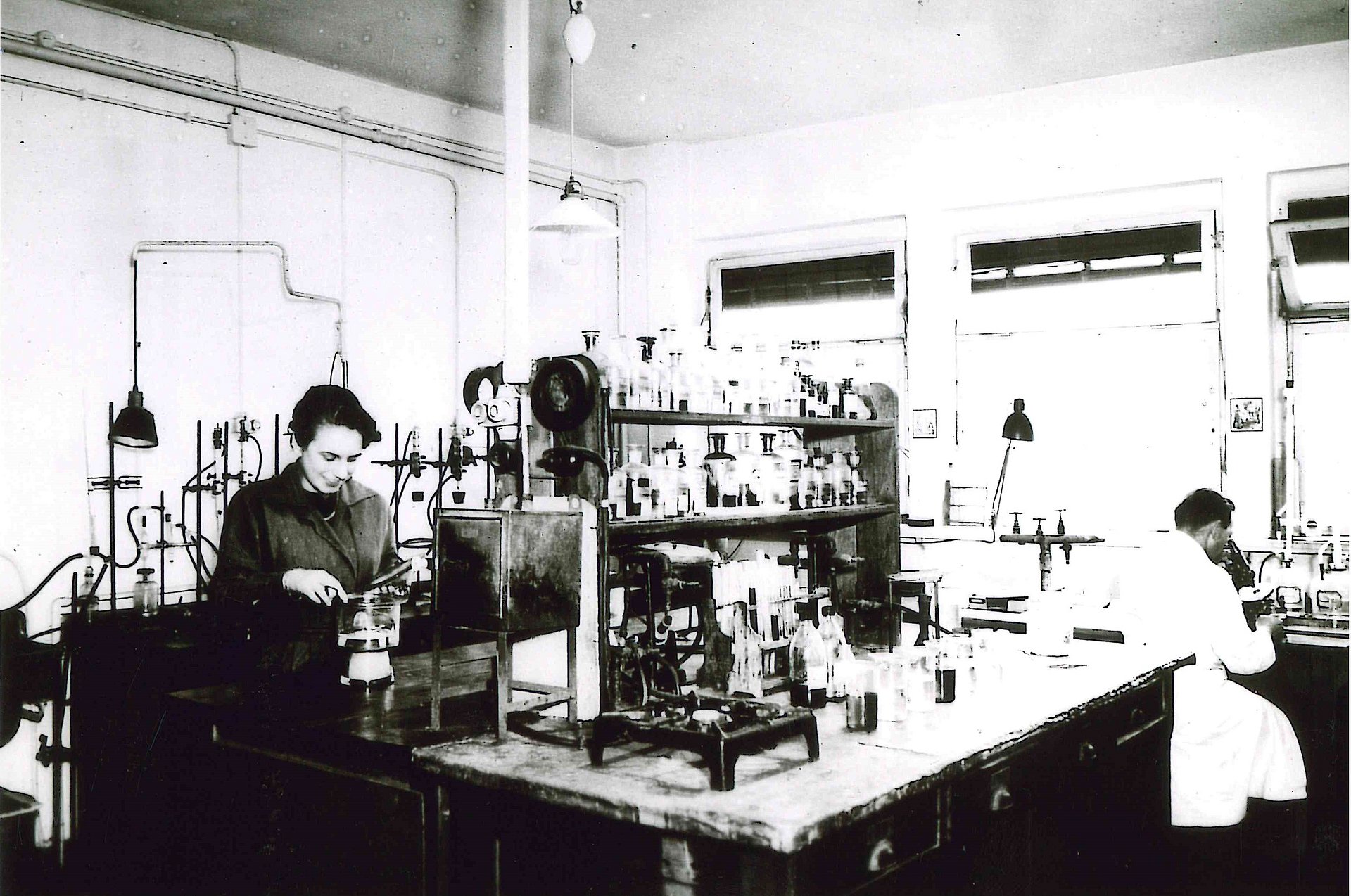

2009 saw the extensive renovation of our in-house laboratory, the nucleus for innovative product development. The investment in modern analytical equipment has enabled us to analyze all existing substances and substance mixtures even more precisely, so that we can use this as a basis for developing innovative, customized customer solutions that meet our own high quality standards.

Today: With an almost 100-year tradition behind us, we are consistently looking ahead. We work on ourselves and continue to develop. To this day, we see ourselves as a fair partner who reliably acts at eye level. Our customers can rely on this at all times: We take on all challenges related to cleaning and corrosion protection. This way you keep your head clear and can fully concentrate on what is actually the focus of your business.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.